BD SCF™ PremiumCoat® Plunger Stopper

The advanced plunger stopper designed with innovations to help you de-risk and develop your next biologic

- Overview

- Products & Accessories

- Resources

Designed to power your next biologics breakthrough

BD Medical – Pharmaceutical Systems is a supplier of ready-to-use plunger stoppers for prefillable syringes.1 To help pharmaceutical companies like yours optimize functional performance when developing new biologics, we've optimized the key components of our advanced plunger stopper. The result is the BD SCF™ PremiumCoat® 1-3mL Plunger Stopper, with multiple design innovations to help you address your evolving needs as you develop your next drug combination product.

Look closer at the BD SCF™ PremiumCoat® Plunger Stopper

Click on each design component to see how we’ve innovated every small essential detail to address your emerging challenges of patient safety, high viscosity, compatibility, flexibility and system integration

Improved functional performance

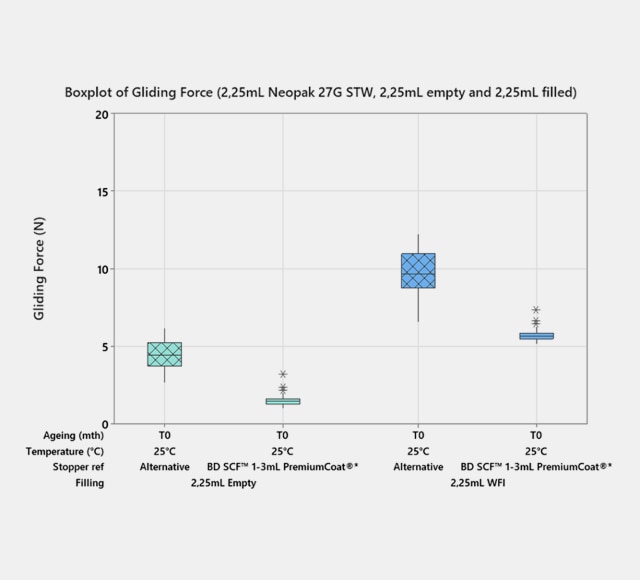

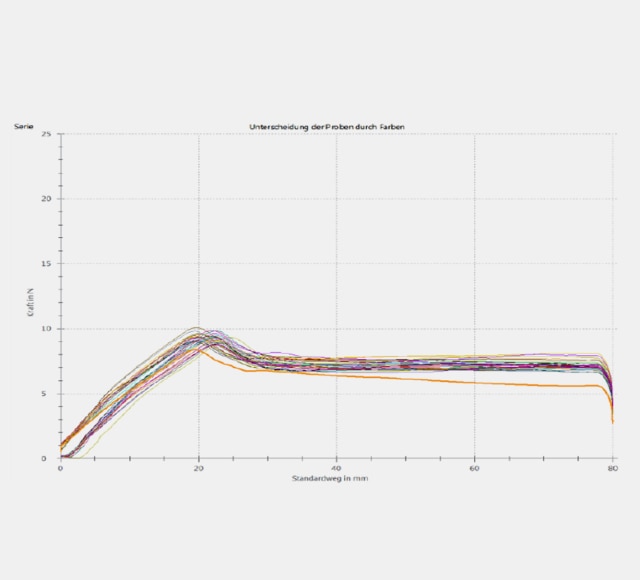

BD SCF™ PremiumCoat® 1-3mL Plunger Stopper was shown to reduce glide force by up to 51% and glide force variability by up to 73%, helping to reduce injection time and injection time variability when part of a drug delivery system^5

Reduce defects

100% camera inspection using BD Visioguard™ for the BD SCF™ PremiumCoat® 1mL Plunger Stopper to help reduce the risk of foreign matter contamination, improve operational efficiency and deliver with tight specifications#7

Increase stopper processability

BD SCF™ PremiumCoat® Plunger Stopper is designed to require less force for assembly when using a vent tube, generate lower temperature.

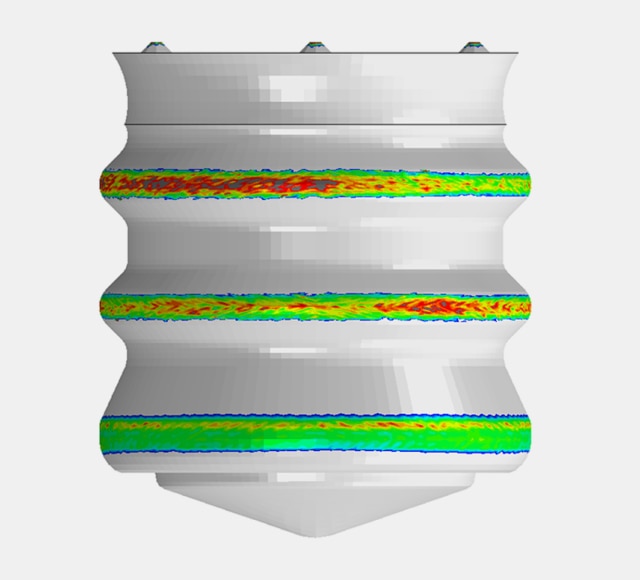

Enable improved CCI*2,3

The BD SCF™ PremiumCoat® Plunger Stopper eliminates the trim contact of the plunger stopper with the barrel, enabling a higher contact pressure between the plunger stopper ribs and syringe barrel as demonstrated by the finite element analysis simulation.*2,3 With the BD SCF™ PremiumCoat® Plunger Stopper, BD guarantees** that all stopper ribs touch inside of the prefilled syringe barrel to support container closure integrity.*2,3

BD offers a robust system data package6,7 to support integration of the BD SCF™ PremiumCoat® Plunger Stopper into combination products, such as with a prefillable syringe and/or autoinjector or safety device.

PremiumCoat is a registered trademark of Aptar Pharma, Inc.

FluroTec is a registered trademark of West Pharmaceutical Services, Inc.

* When compared to the BD SCF™ FluroTec® Plunger Stopper. Results based on a sample of 100 pieces of BD SCF™

Flurotec® and BD SCF™ PremiumCoat.®

† Extractables analysis with glass cane and by immersion showed that the coating provides a barrier effect for a number

of potential extractables in the 6720 formulation, for elemental impurities and semi-volatile and non-volatile

organic molecules.

^ Glide force and glide force variability were tested with BD Neopak™ Glass Syringes and BD SCF™ PremiumCoat® Plunger Stopper System 1mL. Injection time is defined as the time required from the start of the injection (start of stopper translation) to the time required to empty the reservoir or prefillable syringe. Injection time was measured in air with a PEG (polyethylene glycol) filled syrine. Injection time variability refers to consistency of results (or reduced dispersion) for injection time with the BD SCF™ PremiumCoat® Plunger Stopper, BD Neopak™ Prefillable Glass Syringe and 2-steps BD Disposable Autoinjector compared to FluroTec® 1mL. Injection time was measured in air through benchtop testing with the BD SCF™ PremiumCoat Plunger Stopper, BD Neopak™ Prefillable Glass Syringe and 2-steps BD Disposable Autoinjector.

# Damaged coating, ribs damage, removable and non-removable visible particles >1 mm².

§ The glide force measured during Bausch + Ströbel processability tests was done in insertion tube. Alternative stopper

tested is FluroTec®∞ 1mL.

**No "Ribs not touching" after irradiation" criteria in the PremiumCoat® customer specification: Becton, Dickinson and Company. BD SCF™ PremiumCoat® 1-3mL Plunger Stopper Customer quality specification.

SCF: Sterile Clean and ready to Fill. CCI: container closure integrity.

- BDM-PS sales analysis [internal analysis]. Pont-de-Claix, FR: Becton, Dickinson and Company; 2023.

- Becton, Dickinson and Company. TR20234488 Le Pont-de-Claix, France; Becton, Dickinson and Company; 2024.

- BD SCF™ PremiumCoat® 1-3mL Plunger stopper finite element analysis simulating contact pressure [internal study], Pont-de-Claix, FR: Becton Dickinson and Company; 2022.

- Becton, Dickinson and Company. BD SCF™ PremiumCoat® 1mlL Plunger stopper simulated extractables and leachables study [internal study]. Pont-de-Claix, FR: Becton Dickinson and Company; 2019. Similar results expected for 1-3mL.

- Becton, Dickinson and Company. TR20234488 Le Pont-de-Claix, France; Becton, Dickinson and Company; 2024.

- Design Control Evidence BD SCF Premiumcoat 1mlL with integrated biologics system data in Neopak Syringes. Le Pont-de-Claix, France; Becton, Dickinson and Company; 2021.

- Design Control Evidence BD SCF Premiumcoat 1-3mL with integrated biologics system data in Neopak Syringes. Le Pont-de-Claix, France; Becton, Dickinson and Company; 2024.

Our collection of literature on industries and on our offerings gives you information you can use to continue striving for excellence.